Quality made in

Lorandi

Pneumatic handling systems: why choose them

Faster conveying

With a dedicated pneumatic handling line it is possible to greatly accelerate the transport of the raw material, from the arrival at the factory to the processing phase.An automated department

Thanks to pneumatic conveying, everything happens automatically, without the need to physically move pallets of material from one point to another in the plant.More efficiency

In addition to ensuring a high flow rate, pneumatic handling makes it possible to eliminate the loss of material due to human error and to rationalise production.Greater safety

For some sectors, such as the food industry, safety comes first: a pneumatic conveying system avoids handling raw materials, keeping the product intact until packaging.A human-sized system

The effectiveness of a technology is not only evaluated in terms of production performance: pneumatic handling replaces man in many tiring and risky operations, also helping to improve the quality of work.MODULPIPE technology:

the modular and

TAILOR-MADE

pneumatic conveying system

Your implant,

not just any

Versatile, modular,

integrated

Different products – such as cereal grains, legumes or plastic flakes – have different dimensional characteristics and weight: consequently, their behaviour within a pneumatic conveying line also changes.

For this, each element of the line must be adapted to the specifications of the raw material transported and the entire system – propulsion, pipes, curves, valves and arrival – must be designed according to these specificities.

MODULPIPE allows to make the most of the advantages of pneumatic handling: each system is unique, designed specifically for your production needs and tailor-made for you in every detail.

What distinguishes MODULPIPE from standard pneumatic handling systems is its great versatility: thanks to the modular elements, it is possible to customise and modify each part of the line in a simple and fast way, to adapt it to different raw materials.

The special coupling system allows in fact to join and release pipes and components quickly and without the use of keys or bolts: a solution that allows you to intervene independently even in case of maintenance, cleaning or repair.

In addition, each MODULPIPE pneumatic conveying system is able to communicate with the company’s MES and ERP systems thanks to customised software, developed by the IT division of the LORANDI group, which offers you the possibility to manage, monitor and analyse the entire process (even remotely), optimising each phase and instantly identifying any critical issues.

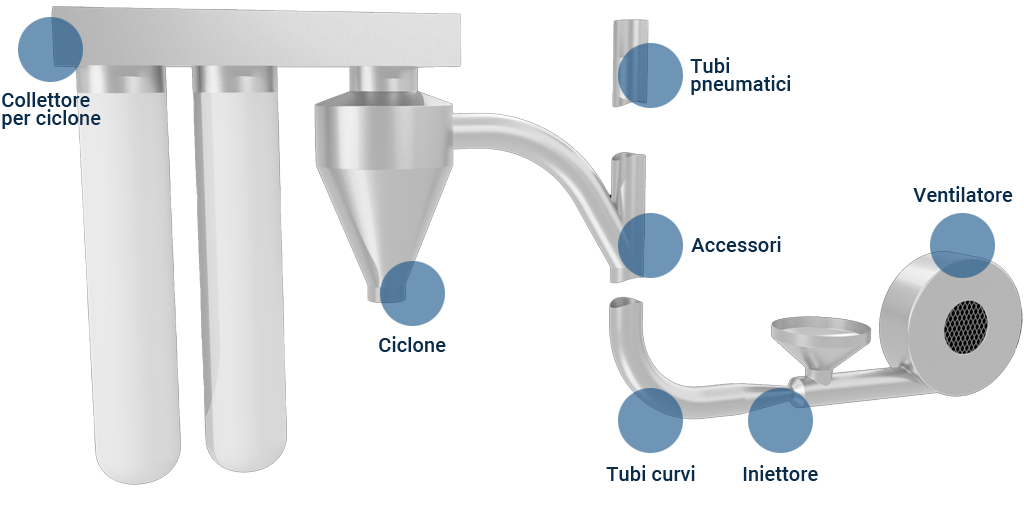

Inside a MODULPIPE pneumatic handling line

How it works

PROPULSION

The raw material enters the

pneumatic handling system through a hopper and is conveyed into a Venturi system (which generates pressure by increasing the thrust) by a closed-bladed fan, which sucks air laterally and introduces it into the line.

If it is not possible to load the material with a homogeneous and constant dosage, a star valve must be inserted to regulate the inlet and avoid clogging.

PIPING

To allow the material to reach the maximum possible speed, the first two metres of the line are straight and horizontal. Then, a curve is inserted to bring the product to height and exploit the upper part of the premises, freeing up useful space for vehicle manoeuvres or for other machinery. The path of the pneumatic handling line can therefore be designed at will according to the needs and architectural characteristics of the production site, while the flow can be interrupted or diverted through pneumatic or electro-pneumatic valves and diverters.

ARRIVAL

In the areas where the raw material must be discharged for processing, a cyclone is inserted in the pneumatic conveying line, which has the function of dividing the air from the product that falls by gravity at the point of destination. The choice of cyclone or hypercyclone model which, like each element of the system, can be customised – will depend on the type of material, the quantity transported and the power of che ogni elemento dell’impianto può essere personalizzato – dipenderà dal tipo di materiale, dalla quantità trasportata e dalla potenza del fan.