Pneumatic conveying:

the noise issue

The LORANDI solution for TUBES ACOUSTIC INSULATION

Addressing the issue of noise on a pneumatic handling line is by no means a simple task and is due to the size of the system, its layout and the large number of components to be soundproofed.

Molte delle soluzioni più diffuse utilizzano materiali come la lana di roccia, che porta quasi a raddoppiare il diametro del tubo, e spesso si è anche costretti ad acquistare svariati pezzi nuovi, se non l’intera linea.

Many of the most common solutions use materials such as rock wool, which almost doubles the diameter of the pipe, and often involves buying several new pieces, if not an entire line.

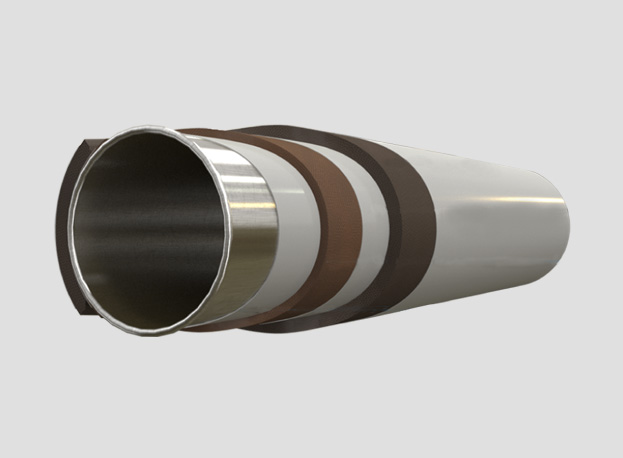

This is why we have developed a tube acoustic insulation system that can be adapted to all pneumatic conveying plants: a customised, handmade system that ensures optimum soundproofing performance, whatever the components it is fitted on.

Acoustic insulation of tubes, bends and cyclones

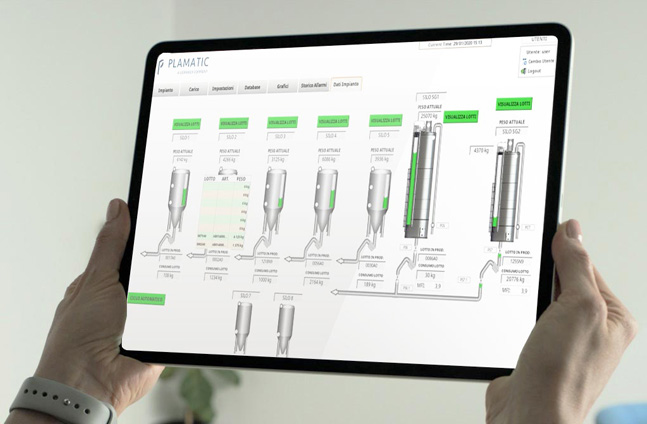

Our insulation system is easily adaptable to virtually any component on the line: straight tubes, bends, cyclones

Each component is hand-crafted using sheets of sound-absorbing material, shaped to measure, glued to the part and coated with a nylon yarn sheath that keeps everything perfectly coupled, preventing it from coming apart as a result of wear or temperature fluctuations.

Soundproof cabins for fans

To reduce the main source of noise on a pneumatic handling line, we have developed specially designed soundproof cabins for fans, available in different sizes to fit the various centrifugal fan models.

Made of steel and carbon with sound-absorbing panels, our soundproof cabins for fans are equipped with a double opening hatch for convenient fan maintenance and cleaning.

Why choose a LORANDI TUBE ACOUSTIC INSULATION SYSTEM

NOISE REDUCTION LEVEL OF OVER 15 dB

Noise levels produced by a pneumatic handling line depend largely on the hardness and granule size of the material being conveyed.

EXTREMELY SMALL CHANGE IN FOOTPRINT

Many other soundproofing systems use bulky materials, which causes a considerable increase in the footprint of each individual component, which can even double in size.

The LORANDI tube acoustic insulation system limits the increase to a few millimetres, compared to a minimum of 5/6 centimetres for other commercially available solutions.

INTERVENTION ON AN EXISTING LINE

It is no longer necessary to replace the noisiest system or its components with new, soundproofed assemblies to reduce the noise of a pneumatic conveying line.Our technicians will design and build a tube acoustic insulation system for an existing line, renovating it and making it quieter, allowing the customer to optimise their resources.

BESPOKE ACOUSTIC INSULATION

Ours is not a standardised product – we work with customers step by step to understand their needs and analyse the system to identify the best performing solutions. Each assembly is custom-made by hand to optimally fit the shape and size of each component, from pipes to bends to cyclones.