THE REQUIREMENTS

Pneumatic handling

Many of our customers deals with production of regenerated HDPE, PP and PS granules, receiving waste plastic and regenerating it to obtain new, sustainable raw material.

The incoming plastic is sorted, washed and ground or extruded to create a variety of finished products, widely used in the construction, packaging and automotive industries.

Often, the customer’s need is to equip itself with a pneumatic conveying system for the material capable of linking its various processes and optimising production. A system that needed to be fast, efficient, reliable but also flexible, so that it could be modified and implemented to keep pace with the company’s growth.

LORANDI'S RESPONSE

MODULPIPE pneumatic conveying

For many of our customers, the optimal solution cannot come from a standardized technology: the goal is to find a partner capable of continuously supporting it in optimizing processes.

After initial work on the storage plant,

we work together with the customer to create a tailor-made pneumatic handling system to track all stages of production, exploiting the potential of MODULPIPE’s modular technology.

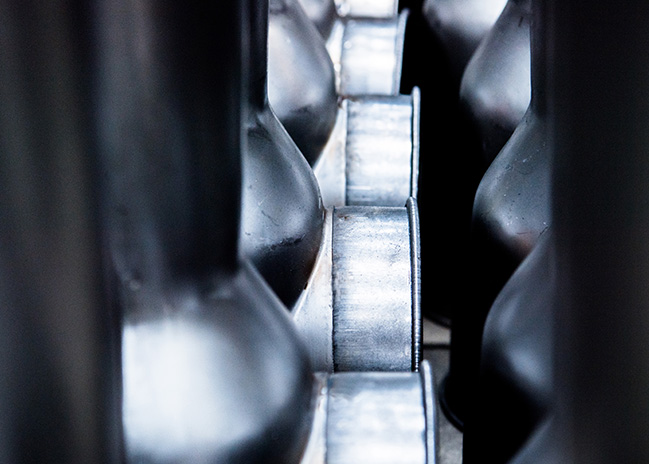

All our components can be found throughout the various lines: centrifugal fans, injectors for pneumatic conveying, rotary valves, cyclones, cyclone manifolds, hot air diffusers and many other components, all of which are customised.

Moreover, the overall and individual performances of each part are continuously monitored to improve efficiency and develop new solutions from scratch, when required.

MODULPIPE SOLUTIONS

Some examples of implementation on pneumatic handling lines

SELECTION AND CLEANING OF INCOMING MATERIEL

NEEDS

Selecting the ideal product by eliminating waste and impurities from the material entering the pneumatic conveying system.

SOLUTION

We installed T-Cleaner air separators on the line, which can separate material of different specific weights. At the same time, we fitted diverting valves to bypass the T-Cleaner for products that do not need to be cleaned or sorted.

INCREASED PRODUCTION

NEEDS

Adapting existing pneumatic handling systems to increased production output.

SOLUTION

The necessary components were replaced to adapt the lines to the incorporation of new machinery, even modifying their layout and configuration to increase production volumes.

COMPONENT WEARE

NEED

Resolving the problem of wear and tear on certain system parts, particularly bends.

SOLUTION

We took action in two ways: on the one hand by inserting enamelled bends, which are more wear-resistant; and on the other hand by increasing the radius of the bends wherever possible, thus making them less susceptible to the impact of the material on the inside of the pipe.

TUBE LENGTHS

NEED’

Adapting standard length tubes to the sizing requirements of the pneumatic conveying line.

SOLUTION

The problem was resolved by using special TLX telescopic tubes, which can be quickly attached with an OR to tubes of various diameters so that each section is the desired length.

NOISE

NEED

Reducing the noise of the pneumatic handling system.

SOLUTION

The various noise sources were isolated: centrifugal fans by means of soundproof cabins for fans; tubes, bends and cyclones by means of our customised tube acoustic insulation system.

MODULPIPE technology for pneumatic handling

MODULPIPE is the most effective solution to all your pneumatic conveying requirements. A versatile, modular response that can be modified and reconfigured as desired without having to replace the entire line.

MODULPIPE stands for convenience, savings in maintenance and reduced risk of breakdowns and production stoppages. But that’s not all: choosing LORANDI technology also means being able to handle most module replacement or cleaning tasks independently, due to the clamping system that allows for quick and straightforward intervention, with no need for spanners or bolts.